|

Sales Engineering Each plant has to be designed and developed on the customer needs. With this concept in our mind, great attention has been put in the development of the Sales Engineering department. A team of management engineers everyday study and develop the most suitable solutions, by merging the company vast know-how and R&D activity to find out new solutions, which guarantee a continuous improvement process. |

|

|

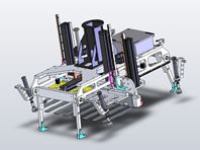

Mechanical Engineering The Mechanical Engineering Office is made by a team of mechanical engineers with a great passion for automation, capable of developing effective and reliable solutions. All workstations have 2D and 3D CAD to design and to model every single component of the plant. The office is equipped with the PDM software, to manage the documentation and to interface with purchasing, production and after sales department. |

|

|

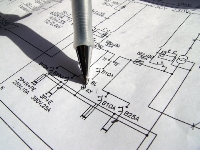

Electrical Engineering The Electrical Engineering Office is responsible of generating the electrical diagrams of the entire plant and to choose the most appropriate electric and electronic components, in coordination with the other departments. The constant and continuous seeking of new components on the market, more precise and more reliable allows to have an extra additional value in our plants. |

|

|

Automation Software The Automation department creates the "soul" of our plants, giving "life" to our machines. Our software technicians can develop various programs for the most know brands (SIEMENS and ROCKWELL) and to manage several robot models (FANUC, ABB, KUKA, DENSO). Aligning with the company philosophy to give the maximum service to the customers, we program ourselves the software used for third party machinery (partner companies) that will be integrated in our plants (stretchwrappers, case erectors, case sealers,...). |

|

|

Supervision software The supervision software department develops the interfacing systems that interconnect OASI.S PLANTS with the customer's hosts (MRP, ERP,...) to enable the advanced data management such as: loading/unloading of work process order, label data management, production measuring,... Moreover, OASI.S has developed a dedicated suite for production management&monitoring , RTPS suite |

|

|

Production & assembly With over 2500sqm available, the production area is the place in which every plant is assembled and wired by our specialized team of technicians. The high precision semi-finished components are produced internally using our company subsidiary located in Refrontolo (TV) where high-skilled personnel realizes these components using lathing and milling machining centres. The components' mechanical work and coating are realized with our local partner companies, lowering the overall costs and lead times. The plants are always internally tested to evaluate their functionalities in order to be sure that are aligned with the customer's expectation; the customer itself can be present during these tests. |

|

|

After sales OASI.S provides to its customers assistance and preventive maintenance services, ensuring in 12h the remote connection assistance and in 24/48h the intervention for electrical/mechanical issues. |

- +39 0423 723921

- info@oasis.to

Office

OASI.S Srl

via della Borsa, 12

I 31033 - Castelfranco Veneto (TV)

t. +39 0423 723921 - f. +39 0423 744472

C.F. e P. IVA 03435980267

CCIA ( TV-1999-3412 ) - REA 272700

Cap. soc € 100.000,00 i.v.